Chart confirms orders for Babcock’s ecoSMRT® LNG boil-off gas recovery system [Promoted]

Chart confirms 12 brazed aluminum plate fin heat exchanger orders for Babcock’s ecoSMRT® LNG boil-off gas recovery system

|

The characteristics of a Chart BAHX are fundamental to ecoSMRT® offering greater efficiencies and being more cost effective than competing technologies. |

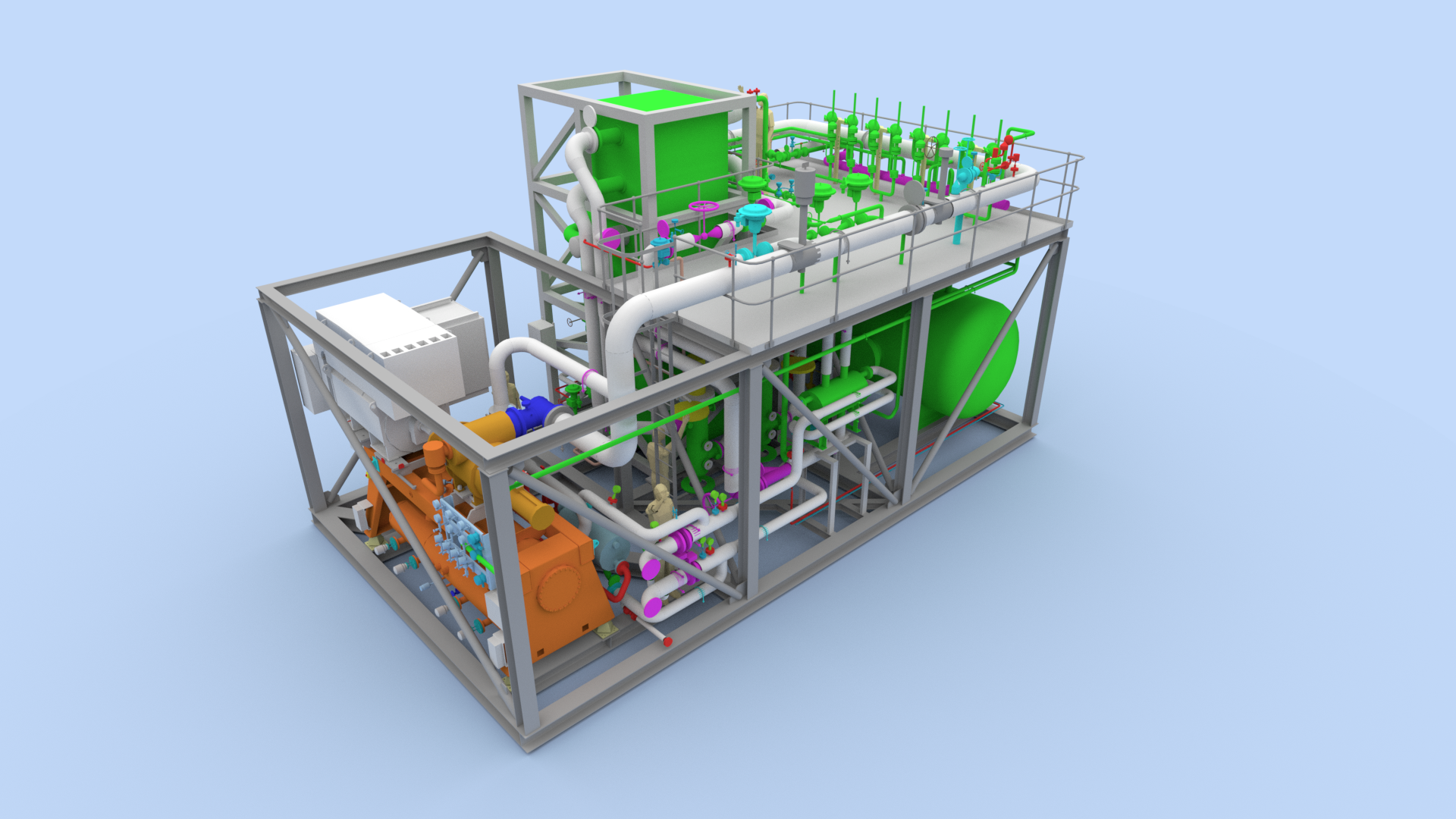

Chart Energy & Chemicals, Inc., a subsidiary of Chart Industries, Inc., (Nasdaq:GTLS), has been awarded a contract by Babcock to provide brazed aluminum plate fin heat exchangers (BAHX) for its patent-pending ecoSMRT® LNG reliquefaction system that recovers excess boil-off gas on-board LNG vessels. Boil-off gas recovery is fundamental to increasing cost efficiencies and environmental credentials of today’s LNG ship fleets and ecoSMRT® is a highly versatile solution that can be installed on new vessels as well as retro-fitted onto older ships, and deployed on both large and small carriers as well as bunkering vessels.

|

Advertisement: The National Gas Company of Trinidad and Tobago Limited (NGC) NGC’s HSSE strategy is reflective and supportive of the organisational vision to become a leader in the global energy business. |

ecoSMRT® image reproduced courtesy of Babcock LGE

BAHX characteristics are fundamental to ecoSMRT®’s key features. The multi-stream capability enables an ecoSMRT® plant to incorporate single mixed refrigerant (SMR) cooling within the BAHX, which removes the need for a separate refrigeration plant. The turndown capability of BAHX enables ecoSMRT® to operate at 30% to 100% reliquefaction capacity to match the boil-off gas system requirements. Engineers at both Babcock and Chart have also worked extensively on the overall design to ensure that the system is as compact and lightweight as possible.

George Arnett, Chart Energy & Chemicals, Inc. VP Global Energy Sales & Marketing said: “Chart prides itself on being at the vanguard of LNG technology and we are delighted with this latest award and the opportunity to team up with Babcock LGE and assist in introducing a highly innovative solution into the marketplace.”

Neale Campbell, Babcock LGE Managing Director, supported: "Babcock’s recent ecoSMRT® contract to Chart highlights our ongoing collaboration within the LNG market. Similarly, Babcock is developing an increasing footprint across the LPG, ethane and ethylene carrier markets through our supplementary technologies.”

Babcock’s selection of Chart BAHX solidifies its approach to deliver proven, reliable technology. There are more than 500 Chart BAHX in LNG service around the globe, from small peak-shaving plants right through to large baseload facilities, including some built in the 1970’s that are still operating today. As well as land based plants, Chart has also supplied BAHX offshore and it was a Chart unit that earned the distinction of being the first to produce LNG on-board a floating vessel.

Chart Industries pioneered the use of BAHX for cryogenic gas processing in the 1950s and we’ve produced over 13,000 units since. A Chart BAHX is a highly efficient, all brazed and welded compact heat exchange device that offers distinct advantages versus other heat exchanger types. They are designed in accordance with the world’s pressure vessel codes and deployed globally. Our principal design and manufacturing facility is in La Crosse, Wisconsin. Notable Chart firsts include the introduction of vacuum brazing, Core-in-Kettle® and mercury tolerant construction. Additionally, we are continually innovating and investing in our technology and capacity to remain the market leader enabling our customers to maximize their opportunities. Learn more at www.ChartIndustries.com

Babcock International Group:

For more than a century, Babcock has been trusted to deliver bespoke, highly-skilled engineering services. We help customers in the UK and around the world to improve the capability, reliability and availability of their most critical assets within the four market sectors of Marine, Land, Aviation, and Nuclear, underpinned by a deep understanding of technology integration, unique infrastructure, and specialist training.